TOP > ISSUE > Production Process 世界に誇るジャパンデニム

TOP > ISSUE > Production Process 世界に誇るジャパンデニム

Posted on : Sep 11 , 2025

広島県福山市、そして岡山県。世界的に知られるジャパンデニムの生産を支える二つの拠点を巡りながら、オリジナルライン 「EVERYDAY I LIKE.」 の一本のデニムが生まれるまでを追った。

In Fukuyama, Hiroshima Prefecture, and in Okayama, we explored two key centers that sustain the globally renowned production of Japan Denim. Through these visits, we traced the creation of a single pair of jeans from the original line “EVERYDAY I LIKE.”

A textile factory boasting more than a century of history

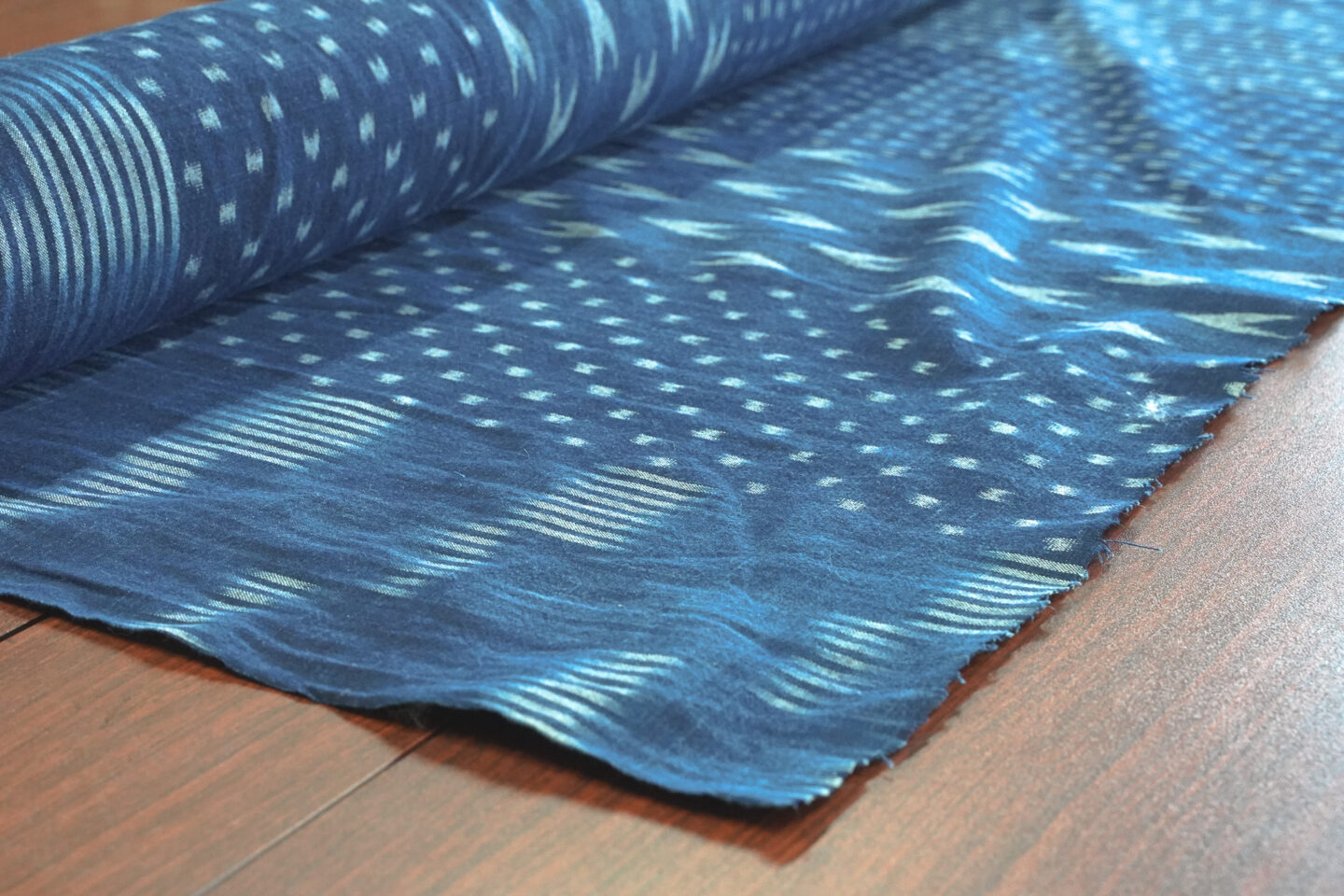

広島県福山市。日本三大かすりのひとつ「備後かすり」の生産をルーツに持つ、創業117年の老舗工場「篠原テキスタイル」を訪れた。

旧式のシャトル織機を扱う数少ない工場のひとつで、その確かな技術にデザイナー小原も信頼を寄せている。

In Fukuyama, Hiroshima Prefecture, we visited Shinohara Textile, a long-established factory with 117 years of history, whose roots lie in the production of Bingo Kasuri, one of Japan’s three major kasuri textiles.

As one of the few factories that still operate traditional shuttle looms, its reliable craftsmanship has long earned the trust of designer Ohara Asako.

シャトル織機は、タテ糸にもヨコ糸にも負担をかけないよう、時間をかけて丁寧に織り上げるのが特徴。ゆっくりと織り進めることで、表面に自然な凹凸が生まれ、奥行きのある表情をもった生地が仕上がる。

The shuttle loom is characterized by its gentle weaving process, placing little strain on either the warp or the weft. By advancing slowly and carefully, it produces a fabric with a naturally uneven surface and a rich, textured depth.

色目を整えた糸の束は工場へと運び込まれ、2,000~8,000本もの糸を、職人が一本も間違えることなく手作業で通していく。効率性とはかけ離れた工程だが、そこにこそ熟練の技術と経験が必要不可欠だ。

Bundles of color-adjusted threads are brought into the factory, where artisans carefully thread between 2,000 and 8,000 strands by hand, without a single mistake. Far from an efficient process, it is one that demands the irreplaceable skill and experience of seasoned craftsmen.

現在は新しいシャトル織機の製造は行われていないため、廃業した工場から機械を譲り受け、メンテナンスを繰り返しながら部品を循環させ、命をつなぐように受け継がれている。

その一方で、電子制御によるエアージェット機も導入し、高速かつ安定した生産体制を整えている。

Since new shuttle looms are no longer being manufactured, the factory acquires machines from closed facilities, circulating parts through repeated maintenance to keep them alive across generations.

At the same time, electronically controlled air-jet looms have been introduced, enabling a high-speed and stable production system.

風合い豊かなシャトル織機と、安定供給を叶えるエアージェット機。どちらの強みも理解し、製品に合わせて最適な方法を選択することが大切だ。

The richly textured shuttle looms and the high-efficiency air-jet looms each have their strengths. Understanding both and selecting the optimal method according to the product is essential.

The Power of Division of Labor in a Sewing Factory

篠原テキスタイルからほど近い場所にある縫製工場。

ここでは、パターン通りに裁断された生地が運び込まれ、6〜10名のスタッフが持ち場につき、パーツごとに分業を行う。わずか3日余りで500本ものデニムが完成するという。

A sewing factory located not far from Shinohara Textile receives fabrics cut according to patterns. Six to ten staff members take their positions, working in a division of labor by parts. In just over three days, they complete as many as 500 pairs of denim.

カジュアルウェアの代表格であるデニムは、効率的な分業体制のもとで縫製されることが多い。厚みのある硬い生地を美しく仕上げる作業は、決して簡単なものではないが、職人の手によってスムーズに進んでいく。積み重ねられた経験と技術が、確かな品質を支えている。

Denim, a staple of casual wear, is often sewn under an efficient system of division of labor. Working with thick, stiff fabrics is by no means easy, yet skilled artisans handle the process smoothly. Their accumulated experience and craftsmanship underpin the fabric’s reliable quality.

最後に訪れたのは、岡山に拠点を構える加工工場「Wells」。ここは、デニムに個性を与える“最後の砦”ともいえる場所だ。

Denim’s Texture Crafted by Hybrid Processing Techniques

The final stop was Wells, a finishing factory based in Okayama. This is the place often described as the “last stronghold,” where denim gains its unique character.

まず案内されたのは、手作業の加工場。木工用の機械を応用した削り、シェービングなど、多彩な加工技術が分業制で行われ、一つひとつのパーツに独自の表情が刻まれていく。

The first stop was the manual processing area. Various techniques—such as shaving and cutting adapted from woodworking machinery—are carried out under a division-of-labor system, giving each individual part its own distinctive character.

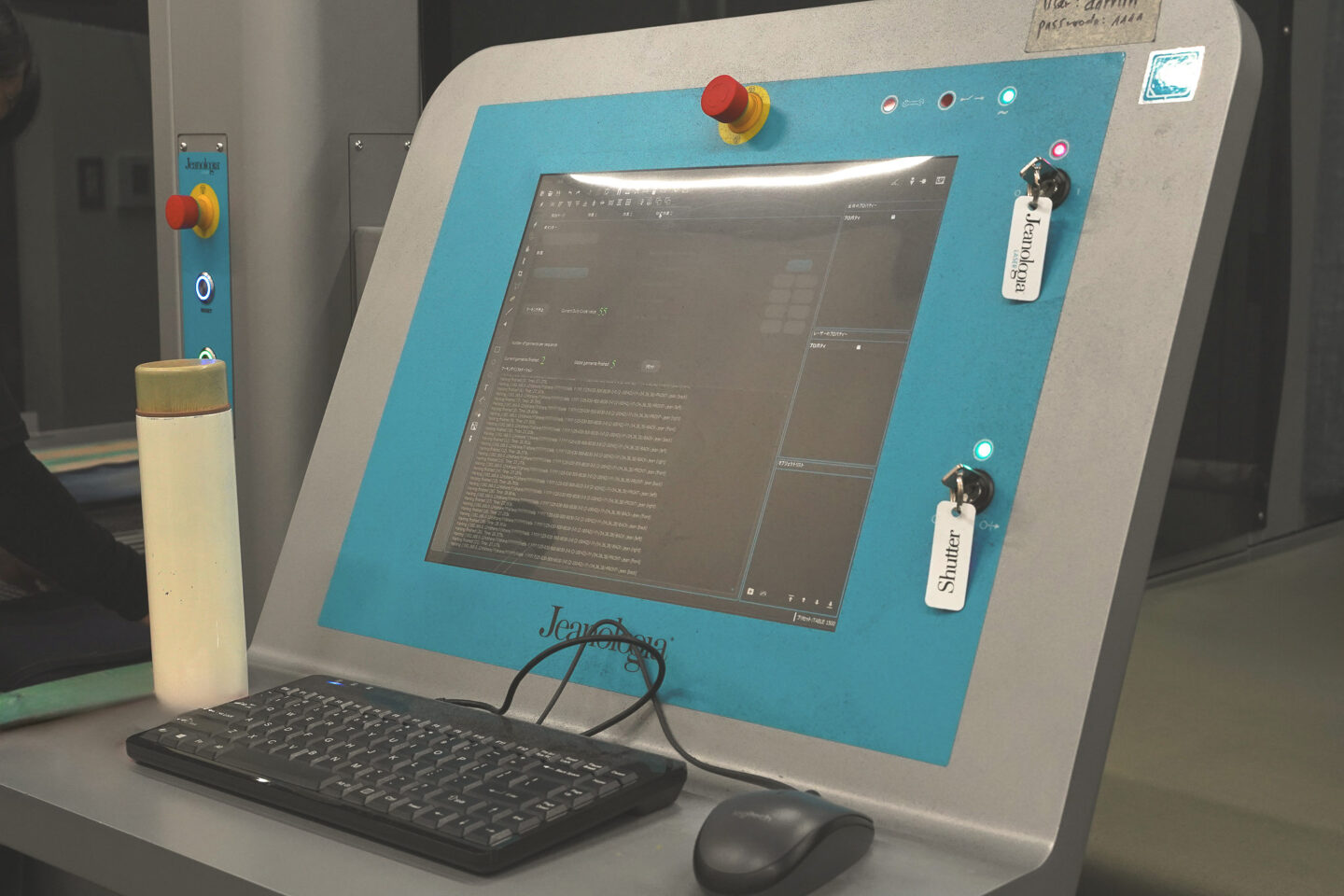

同時にWellsでは、新しい技術の導入も行なっている。その代表が今回のデニムでも使用されているレーザー加工機である。デザインをPCに落とし込み、コンピューターシステムで管理されたレーザー機にデニムをセットする。

At the same time, Wells is also adopting new technologies. A notable example is the laser processing machine used in the denim we saw on this visit. Designs are created on a computer and then transferred to a laser machine, where the denim is precisely set and controlled by a computerized system.

丁寧にプレスをかけた後、前後左右からレーザーを照射し、瞬時に加工が施される。

機械化によってスピードと安定性が確保されるが、ポケットまわりなど細部のディテールは職人の手に委ねられる。

After carefully pressing the denim, lasers are fired from all sides—front, back, and sides—instantly applying the desired effects.

While mechanization ensures speed and consistency, finer details, such as around the pockets, are still entrusted to the hands of skilled artisans.

さらに、洗いや色を重ねる「トッピング」と呼ばれる工程を経て、何度も洗いと乾燥を繰り返すことで奥行きのある風合いが生まれる。

Furthermore, through a process called “topping,” which involves layering washes and colors, the denim undergoes repeated washing and drying, creating a rich, textured depth.

パッチやボタンの後加工、ベルトループの糸始末、最終的なプレス仕上げを施す専用工場へと運ばれ、ようやく一本のデニムが完成する。幾重にも重ねられた工程の積み重ねが、一本のデニムを形づくっている。

The denim is then sent to a dedicated factory for finishing touches, including patch and button work, thread trimming on belt loops, and final pressing. Only after these steps is a single pair of jeans complete. It is the accumulation of these layered processes that gives each pair its form and character.

かつて主流だった手作業による生産は、いまや次世代へと受け継ぐべき貴重な技術となっている。

一方で、時代の変化に合わせて工場の在り方も常に進化を続けている。

安定した供給や均一な品質を実現するための機械導入、さらにデザインの再現性や納期といった多様な要望に応えるには、柔軟な取捨選択が求められる。

そうした中で、デザイナーと各工場をつなぎ、両者の思いを橋渡し、信頼関係を築き上げるコンバーターの存在は必要不可欠だ。

数えきれないほどの工場と、そこに込められた人々の想いを乗せて完成する、EVERYDAY I LIKE. のデニム。それは単なる製品としてだけではなく、積み重ねられた技術と信頼の証として、お客様のもとへと届けられている。

Finally, what was once a mainstream practice of handcrafting has now become a precious skill to be passed on to the next generation.

At the same time, factories continue to evolve in response to changing times. The introduction of machinery ensures stable supply and consistent quality, while meeting diverse demands—such as design fidelity and delivery schedules—requires flexible decision-making.

In this context, converters play an indispensable role, connecting designers with factories, bridging their visions, and building trust.

The denim of EVERYDAY I LIKE. is the result of countless factories and the dedication of countless people. It is delivered to customers not merely as a product, but as a testament to accumulated craftsmanship and trust.

編集後記

工場のご案内をしてくださったコンバーター田口さんに紹介していただいたうどん屋さんを訪れ、倉敷の美しい街並みにも触れることができた今回の取材。ものづくりの現場と土地の魅力をあらためて感じる旅となりました。

After being introduced by Mr. Taguchi, the converter who guided us through the factories, we visited a recommended udon restaurant and also explored the beautiful streets of Kurashiki. This trip offered a renewed appreciation for both the craftsmanship we observed and the charm of the local area.

[写真1-3]コシの強いしっかりとした手打ち麺に、名物の大判のかき揚げが乗った天ぷらうどん。セルフで選べるおでんも絶品。(店名:手打ちうどん たぐち)[写真4]倉敷美観地区の美しい町並み

[Photos 1–3] Tempura udon topped with a generous, signature kakiage, served with firm, chewy hand-pulled noodles. The self-service oden is also excellent. (Restaurant: Teuchi Udon Taguchi)

[Photo 4] The picturesque streets of Kurashiki’s Bikan Historical Quarter.